Introduction

Aircraft Body Defect Detection

Aerospace Maintenance, Repair, and Operations (MRO) face significant challenges when it comes to the precise and efficient identification of defects, as well as ensuring timely maintenance procedures. These challenges can result in a cascade of issues, including potential delays, elevated operational costs, and heightened risks to the safety and overall reliability of aerospace systems.

Challenges

Challenges Encountered in Aircraft Defect Inspection.

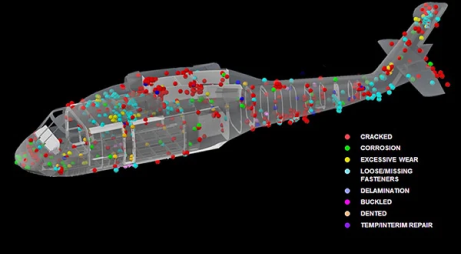

Inaccuracies in Defect Identification

Aircraft and aerospace systems, with over 50 possible defects, pose challenges in detection, especially for hidden parts. Advanced tech and skilled personnel are vital for safety and reliability.

Limited Real-world Data Availability

Obtaining a comprehensive dataset of real-world aircraft surface defects can be very challenging and expensive. Most of the time, the defects may have only occured once, which makes it hard to train the defect recognition system effectively.

Scalability of Machine Learning Training

Defects frequently involve intricate and diverse scenarios from surface defects to potential hardware malfunctions, making it challenging to replicate them on actual aircraft materials. Moreover, this approach is cost-ineffective.

Sigmawave’s Solutions

Transforming aerospace maintenance, Sigmawave uses visual synthetic data to expedite aircraft defect detection:

Fully Customizable Visual Synthetic Data by Terra Builder

Terra Builder’s artificial data models revolutionize video analytics with 100% customizable, programmable visual synthetic data, precisely tailored for specific defect analytics and tracking system.

Development of Specialized Algorithms for defect and hardware malfuntion Detection

Develop specialized algorithms for defect and hardware malfuntion detection, uniquely designed to identify rare scenarios and conditions.

Diverse Defects Classification

Sigmawave’s image generation capabilities replicate various maintenance scenarios, provide classification of defects instantly, and reducing overall downtime for more efficient aircraft maintenance.

Benefits

Unlocking Benefits in Military Applications with Sigmawave AI

Precise and Effective Scenario Representation

Sigmawave harnesses visual synthetic data to simulate a wide range of scenarios, expediting aircraft defect identification. This innovative approach saves both time and money compared to conventional methods, emphasizing efficiency and cost-effectiveness.

Minimized Hangar Stays

The platform’s image generation capabilities allow for the replication of various maintenance scenarios. By simulating these scenarios, Sigmawave minimizes hangar stays, reducing the overall duration and cost of aircraft maintenance.

Efficient Resource Allocation

Through accurate identification of defects and loose hardware items, Sigmawave facilitates more efficient resource allocation during maintenance. This, in turn, contributes to significant cost reductions and overall downtime for aircraft.